QuaVis Technologies

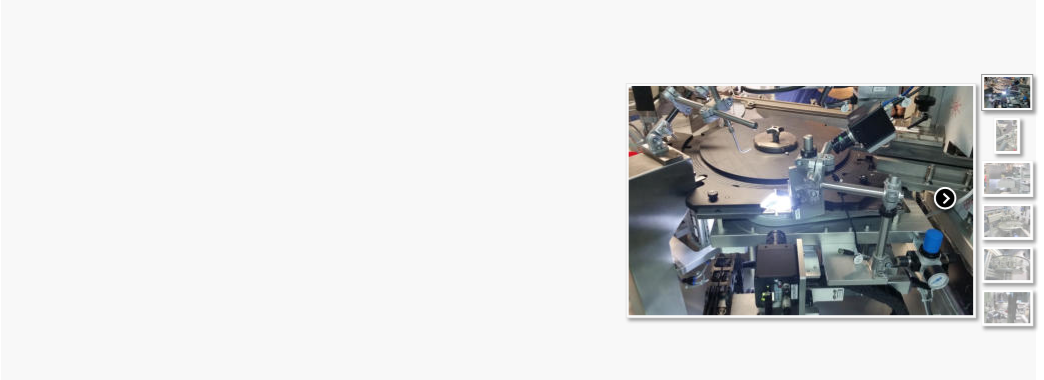

Pace GT

Pace up to 800 parts / minute

This solution works with a 600 mm glass table suitable for all parts which can stand or lay in position, such as washers, nuts and flat parts. In order to avoid noise in the measurement, the feeding unit is normally uncoupled from the measurement unit. This enables the usage of a feeder such as a vibrating bowl, step feeder or a special bowl for heavy parts. It is possible to attach up to 10 inspection stations on one disc allowing parallel testing of different parameters.

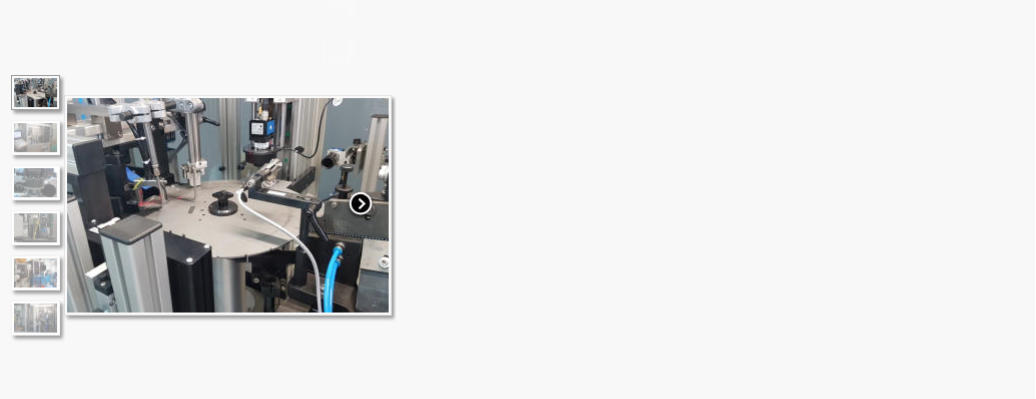

Pace SH

Speed up to 1.500 parts / minute

Shank diameter: M0,7 – M36

Length: 3 mm – 380 mm

PACE SH is a machine using a rotating steel disc in which the parts are moved in a hanging position. Mainly screws, bolts, rivets, etc. As in the Pace GT the feeding unit is equipped in a seperate unit to avoid vibration noise in the measurements. This enables the usage of a feeder such as a vibrating bowl, step feeder or a special bowl for heavy parts. The parts are fed over rotating rollers and rails into the disc. On the rollers the parts getting orientated and pre-selected through their head diameter. The disc (up to 300 mm diameter) can be equipped with 12 – 60 slots to archive the optimum speed related to the parts geometry.RETROFIT and remodeling of old Pace

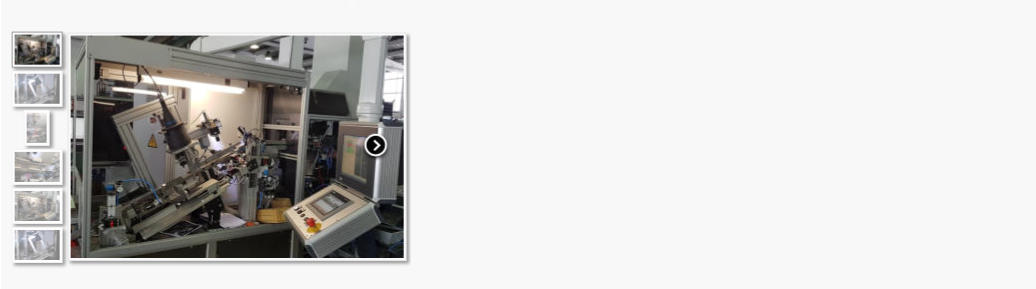

We are able to modernize your old Pace machines. Upgrades can be: New cameras, latest PLC or innovative functions Contact us to be advised on your machine!

Pace V

Speed up to 350 parts / minute

PACE V is an inspection machine for headless parts, axis’s, turned parts, pins, etc. A linear acceleration conveyor transports the parts into the inclined V chute. While sliding down the parts are then inspected via Shank Cameras, Eddy Current and additional Sensorts or Head Cameras. In an optional unit placed before the camera station, the parts can be checked over 360° all over the lateral surface over the total length of the part.

2020 © QuaVis Technologies GmbH

Legal Notice | Privacy | Terms & Conditions

Individual Rotation Inspection

Accuracy: 0,3 degree

Indexing operation up to 210 parts / minute

For an accurate and ZERO ppm guaranteed 360° inspection of cracks and surface defects the parts will rotate. The lift of the part is made with an accurate motor movement with automated servo motor positioning.QuaVis Technologies

Pace SH

Speed up to 1.500 parts / minute

Shank diameter: M0,7 – M36

Length: 3 mm – 380 mm

PACE SH is a machine using a rotating steel disc in which the parts are moved in a hanging position. Mainly screws, bolts, rivets, etc. As in the Pace GT the feeding unit is equipped in a seperate unit to avoid vibration noise in the measurements. This enables the usage of a feeder such as a vibrating bowl, step feeder or a special bowl for heavy parts. The parts are fed over rotating rollers and rails into the disc. On the rollers the parts getting orientated and pre-selected through their head diameter. The disc (up to 300 mm diameter) can be equipped with 12 – 60 slots to archive the optimum speed related to the parts geometry.

Pace GT

Pace up to 800 parts / minute

This solution works with a 600 mm glass table suitable for all parts which can stand or lay in position, such as washers, nuts and flat parts. In order to avoid noise in the measurement, the feeding unit is normally uncoupled from the measurement unit. This enables the usage of a feeder such as a vibrating bowl, step feeder or a special bowl for heavy parts. It is possible to attach up to 10 inspection stations on one disc allowing parallel testing of different parameters.

RETROFIT and remodeling of old

Pace

We are able to modernize your old Pace machines. Upgrades can be: New cameras, latest PLC or innovative functions Contact us to be advised on your machine!

Pace V

Speed up to 350 parts / minute

PACE V is an inspection machine for headless parts, axis’s, turned parts, pins, etc. A linear acceleration conveyor transports the parts into the inclined V chute. While sliding down the parts are then inspected via Shank Cameras, Eddy Current and additional Sensorts or Head Cameras. In an optional unit placed before the camera station, the parts can be checked over 360° all over the lateral surface over the total length of the part.

Individual Rotation Inspection

Accuracy: 0,3 degree

Indexing operation up to 210 parts /

minute

For an accurate and ZERO ppm guaranteed 360° inspection of cracks and surface defects the parts will rotate. The lift of the part is made with an accurate motor movement with automated servo motor positioning.

2020 © QuaVis Technologies GmbH

Legal Notice | Privacy | Terms & Conditions