Smarter Quality Control: AI & Machine Learning in Industrial Inspections

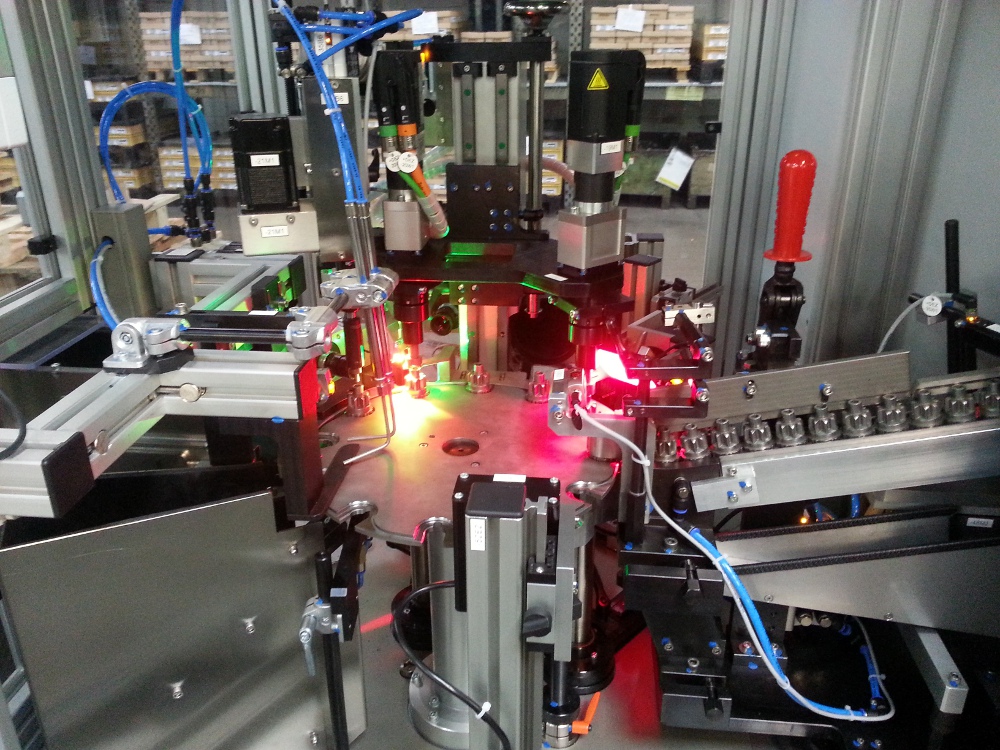

In the fast-paced world of industrial manufacturing, precision and efficiency are not just desirable — they are essential. As product complexity increases and production lines become faster, traditional inspection methods often struggle to keep up. That’s where Artificial Intelligence (AI) and Machine Learning (ML) come into play, revolutionizing how we approach quality control and visual inspections.

What Are AI & Machine Learning Inspections?

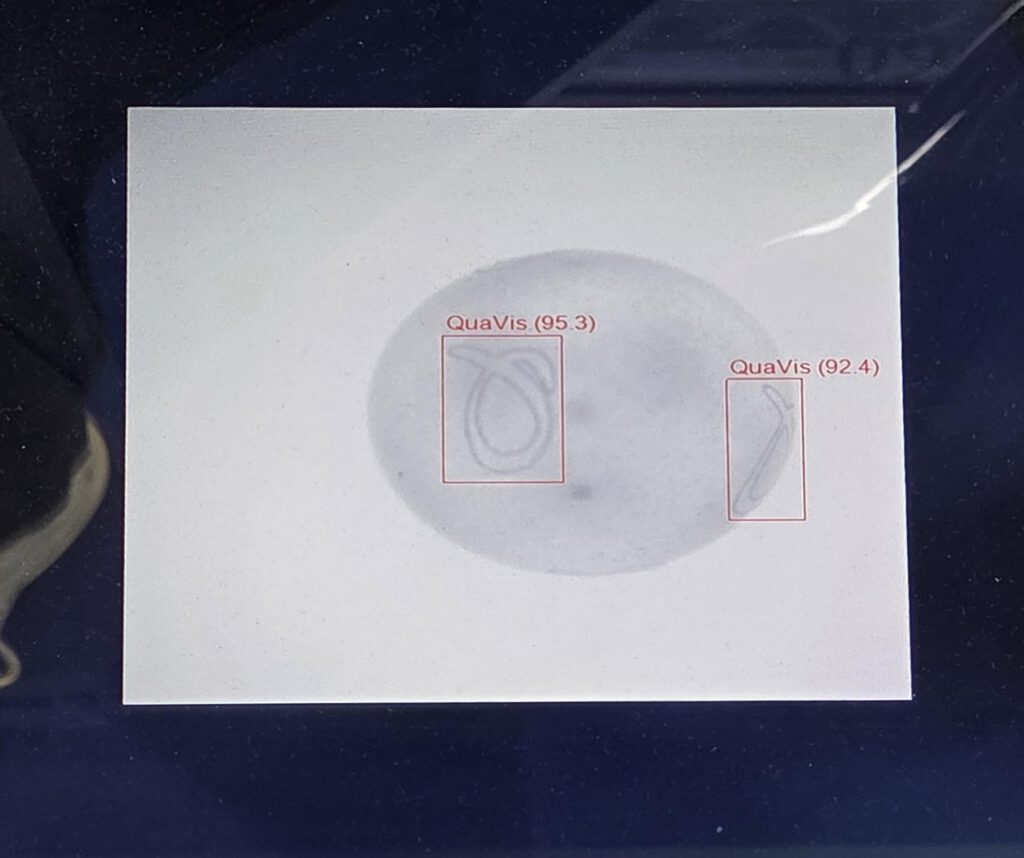

AI and ML inspections refer to automated systems that use intelligent algorithms to detect defects, classify products, and identify patterns in visual data — all without human intervention. Unlike rule-based systems that require manual programming for each defect type, ML models learn from data. They improve over time, becoming more accurate with every inspection cycle.

By training on thousands of images, these systems can detect subtle variations and complex defects that may escape even the most trained human eye or a traditional machine vision system. From surface scratches on metal parts to misalignments in complex assemblies, AI-driven inspections deliver higher accuracy and consistency.

How Do I Deploy AI in My Production Line?

While it might seem overly complicated and tedious to even start thinking about AI or Machine Learning in your production process, deploying it with the right framework is not. Our focus is on enabling our customers to finetune their own AI algorithms or models. We do this by providing an easy and intuitive GUI that comes with our system when needed. With our system, you are able to classify and detect the errors you mark in images yourself and train different models by the click of a button. You then choose the best model for your use case and deploy it to production as easy as clicking a play button.

Benefits That Go Beyond Accuracy

- Adaptability: AI systems can adjust to changes in lighting, orientation, or slight product variations — conditions that would challenge conventional image processing.

- Scalability: ML models can be trained across product lines, making them suitable for everything from microelectronics to heavy manufacturing.

- Predictive Insights: Beyond defect detection, AI enables predictive maintenance and process optimization by identifying trends in inspection data.

Why Experience Matters

Implementing AI & ML for inspections isn’t just about deploying technology — it’s about doing it right. It requires deep knowledge of both image processing and the unique conditions of industrial environments. At QuaVis, we combine decades of machine vision expertise with cutting-edge, OpenSource AI models to deliver turnkey inspection solutions that are robust, reliable, and tailored to your exact needs.

Whether you’re just exploring AI-driven inspections or looking to scale an existing system, our team is here to help you harness the full potential of intelligent automation.