Precision at the Core: Advanced Screw Inspection with Machine Vision

Screws may be small, but their role in industrial manufacturing is critical. Whether holding together components in automotive assemblies or securing parts in electronics, even the slightest defect in a screw can lead to serious performance or safety issues. That’s why high-precision screw inspection is a must — and image processing is the key.

What is Screw Inspection?

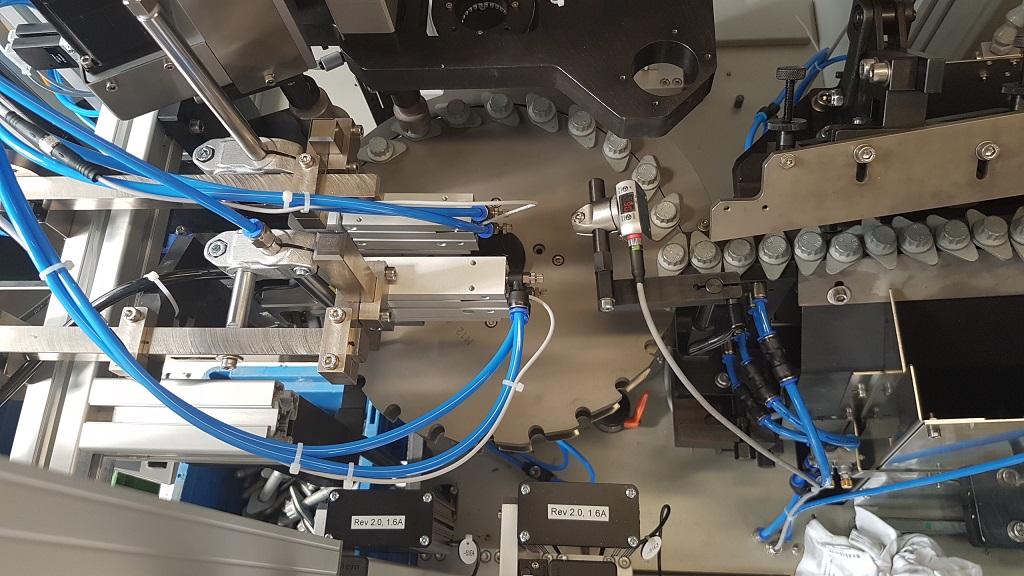

Screw inspection refers to the automated quality control process that evaluates the physical characteristics of screws — such as dimensions, thread integrity, surface quality, and head shape — using high-resolution imaging systems. These inspections can be performed inline, at high speeds, ensuring that only flawless components move forward in the production process.

Challenges in Screw Inspection

Screws may look simple, but inspecting them is anything but. Variations in size, thread pitch, surface reflection, and orientation all add complexity to the inspection process. Traditional methods struggle with consistency, especially at high throughput.

This is where advanced image processing, often combined with AI and 3D inspection technologies, makes a significant impact.

What We Inspect:

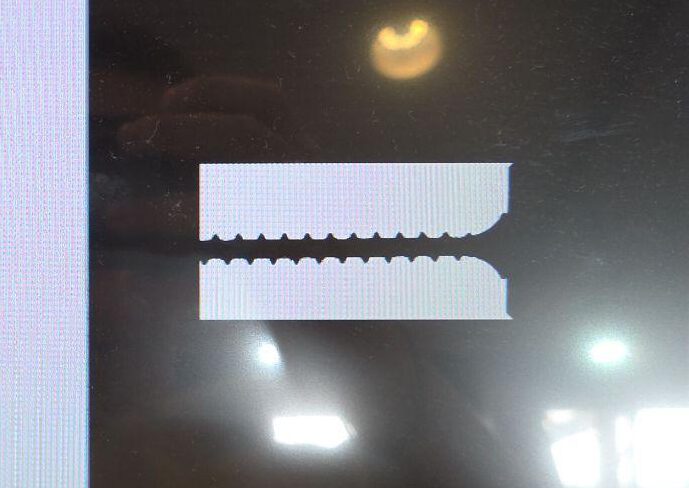

- Thread Presence and Pitch Accuracy

- Length and Diameter Measurements

- Head Type and Drive Shape Verification

- Surface Defects (e.g., cracks, dents, rust)

- Bent or Deformed Screws

- Tip Sharpness and Profile

Benefits of Automated Screw Inspection

- High-Speed Throughput: Our systems can inspect hundreds of screws per minute without missing a detail.

- High Accuracy and Repeatability: Precision optics and software detect even micrometer-scale defects.

- 360° Coverage: With multi-camera and rotating systems, we ensure no defect goes unseen.

- Real-Time Rejection: Defective parts are automatically sorted out — no delay, no compromise.

Why Partner with Us?

At QuaVis Technologies, we specialize in turnkey screw inspection systems tailored to your production line. With years of experience in industrial image processing, we design solutions that integrate seamlessly into your workflow, boosting efficiency and quality control. Our systems are built for durability, accuracy, and adaptability — ready to handle the toughest inspection challenges in any manufacturing environment.