Surface Fault Detection: Finding the Flaws You Can’t Afford to Miss

In industrial manufacturing, surface quality is more than a cosmetic detail — it’s a sign of precision, durability, and trust in your brand. Whether you’re producing machined metal parts, coated components, or plastic housings, even the smallest surface fault can lead to functional failures, product recalls, or customer dissatisfaction.

That’s why Surface Fault Detection powered by advanced image processing is a critical quality control process across modern production lines.

What is Surface Fault Detection?

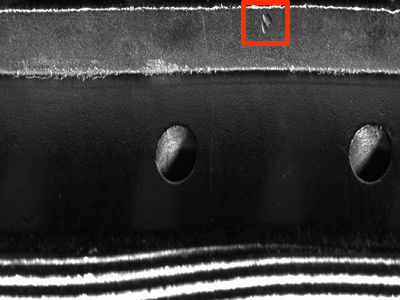

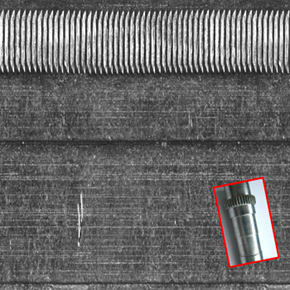

Surface fault detection refers to the automated identification of visual defects on material or component surfaces. These can include scratches, dents, cracks, contamination, pits, blisters, and uneven textures — often too subtle or inconsistent for traditional inspection methods to catch reliably.

By using high-resolution cameras, specialized lighting, and intelligent software, our systems can detect these anomalies in real time, ensuring only flawless parts make it to your customers.

Types of Defects We Detect:

- Scratches, cracks, and scoring

- Dents, pits, and bumps

- Material inclusions or voids

- Surface contamination or discoloration

- Coating irregularities or peeling

- Weld or joint surface inconsistencies

The Technology Behind the Process

Effective surface inspection is all about contrast and consistency. We utilize:

- Controlled Lighting (e.g. dark field, dome, coaxial) to highlight defects without interference from part geometry.

- High-Speed Cameras for capturing defects on fast-moving lines with crisp detail.

- AI & Machine Learning to distinguish between real faults and acceptable surface variations.

- 3D Imaging for depth-based evaluation of texture anomalies.

Our systems adapt to different materials — metals, plastics, glass, textiles — and are built to maintain performance in industrial environments, even with challenging surface finishes like glossy, reflective, or textured parts.

Key Benefits:

- 100% Inline Inspection — eliminate sampling errors and inspect every part, every time

- Early Defect Detection — catch problems before they become expensive downstream issues

- Automatic Sorting — faulty parts are flagged or removed instantly

- Reduced Customer Complaints — consistent surface quality builds trust and satisfaction

Our Edge: Experience + Custom Engineering

At QuaVis, we don’t believe in one-size-fits-all solutions. Surface fault detection is highly sensitive to lighting, material properties, and production speed — and we engineer each system to match your specific product and environment. With decades of expertise in image processing and factory automation, we deliver solutions that just work — reliably, accurately, and at scale.